Introduction

As the CEO of FLUIDMEC, I’ve had the privilege of witnessing the transformative power of PEEK gaskets in industrial settings. In this ultimate guide, I’ll unveil 100 advantages that position PEEK gaskets as the premier choice for challenging environments. Whether you’re an engineer, procurement manager, or maintenance specialist, this list will illuminate why PEEK gaskets are indispensable across diverse industries. Let’s embark on a journey into the realm of high-performance sealing!

Table of Contents

Chapter 1: Thermal Properties

1. Exceptional high-temperature resistance

PEEK’s exceptional high-temperature resistance is one of its most remarkable features. This polymer can withstand continuous exposure to temperatures up to 260°C (500°F) without significant degradation of its mechanical properties. PEEK’s thermal stability allows it to maintain its structural integrity and performance in environments where other plastics would fail. This makes it ideal for applications in industries such as aerospace, automotive, and oil & gas, where components are subjected to extreme heat.

2. Low-temperature performance

While PEEK is renowned for its high-temperature capabilities, it also exhibits impressive low-temperature performance. PEEK remains stable and functional at temperatures as low as -60°C (-76°F), retaining its mechanical strength and impact resistance. This wide operating temperature range makes PEEK an excellent choice for applications that experience significant temperature fluctuations, such as outdoor equipment or components used in aerospace and cryogenic applications.

3. Thermal stability

PEEK’s thermal stability is a key factor in its widespread adoption across various industries. The polymer’s unique molecular structure, consisting of aromatic rings connected by ether and ketone linkages, contributes to its exceptional resistance to thermal degradation. This stability ensures that PEEK maintains its properties even after prolonged exposure to high temperatures, making it suitable for long-term use in demanding thermal environments.

4. Low thermal expansion

One of PEEK’s most valuable properties is its low coefficient of thermal expansion (CTE). PEEK’s CTE is significantly lower than that of many other thermoplastics, ranging from 47 to 108 µm/m-°C. This low expansion rate means that PEEK components maintain their dimensional stability even when subjected to temperature changes, reducing the risk of warping, distortion, or misalignment in precision applications.

5. Thermal shock resistance

PEEK exhibits excellent resistance to thermal shock, which is the ability to withstand sudden and extreme temperature changes without cracking or losing structural integrity. This property is crucial in applications where rapid heating and cooling cycles occur, such as in injection molding processes or aircraft components. PEEK’s thermal shock resistance ensures reliability and longevity in these demanding environments.

6. Heat deflection temperature

The heat deflection temperature (HDT) of PEEK is impressively high, typically ranging from 160°C to 315°C (320°F to 599°F) at 1.8 MPa (264 psi). This high HDT indicates that PEEK retains its rigidity and load-bearing capabilities at elevated temperatures, making it suitable for structural applications in high-temperature settings. The polymer’s ability to maintain its shape and mechanical properties under heat and load is crucial in industries such as automotive and aerospace.

7. Continuous operating temperature

PEEK’s ability to function reliably at high temperatures for extended periods is one of its most valuable attributes. The continuous operating temperature of PEEK typically ranges from 240°C to 260°C (464°F to 500°F), depending on the specific grade and application requirements. This long-term thermal stability makes PEEK an excellent choice for components that must endure prolonged exposure to heat, such as in oil and gas exploration equipment or automotive under-the-hood applications.

8. Melting point

PEEK’s high melting point of approximately 343°C (649°F) is a testament to its exceptional thermal properties. This elevated melting temperature contributes to PEEK’s ability to maintain its solid-state and mechanical properties at high operating temperatures. The high melting point of PEEK also allows for a wide processing window during manufacturing, enabling the production of complex parts through injection molding, extrusion, or additive manufacturing techniques.

9. Glass transition temperature

The glass transition temperature (Tg) of PEEK is around 143°C (289°F), which is significantly higher than many other engineering plastics. This high Tg contributes to PEEK’s excellent dimensional stability and mechanical strength at elevated temperatures. Above the glass transition temperature, PEEK maintains its semicrystalline structure, allowing it to retain much of its stiffness and strength even as it becomes more ductile.

10. Thermal conductivity

While PEEK is known for its excellent thermal insulation properties, its thermal conductivity is relatively low compared to metals. PEEK’s thermal conductivity typically ranges from 0.25 to 0.92 W/m·K, depending on the specific grade and fillers used. This low thermal conductivity makes PEEK an excellent choice for applications requiring thermal insulation, such as in electrical connectors or heat shields. However, for applications requiring heat dissipation, PEEK can be modified with thermally conductive fillers to enhance its thermal management capabilities.

Chapter 2: Chemical Resistance

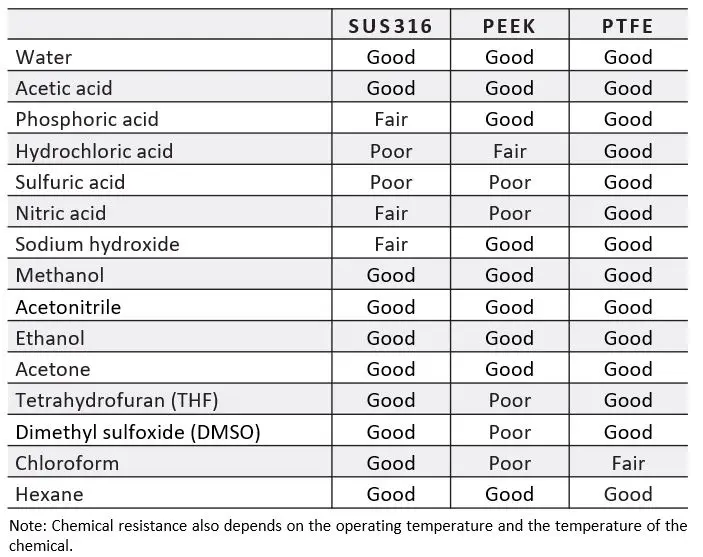

11. Resistance to acids

PEEK gaskets excel in their ability to withstand a wide range of acids, making them indispensable in industries dealing with corrosive chemicals. Their exceptional acid resistance stems from PEEK’s unique molecular structure, which creates a barrier against chemical attacks. PEEK’s acid resistance allows it to maintain its mechanical and physical properties even when exposed to strong acids like sulfuric, hydrochloric, and nitric acid. This resilience ensures that PEEK gaskets can provide reliable sealing in acidic environments where other materials might degrade rapidly.

12. Resistance to bases

The resistance of PEEK gaskets to bases is another remarkable feature that sets them apart from conventional sealing materials. PEEK demonstrates excellent stability when exposed to alkaline solutions, retaining its structural integrity and sealing properties. This makes PEEK gaskets ideal for applications in industries such as chemical processing and wastewater treatment, where exposure to basic compounds is common. PEEK’s base resistance ensures long-lasting performance and reduces the need for frequent replacements, ultimately leading to cost savings and improved operational efficiency.

13. Hydrocarbon resistance

PEEK gaskets exhibit outstanding resistance to hydrocarbons, making them a top choice for oil and gas industry applications. This resistance allows PEEK to maintain its structural integrity and sealing properties when exposed to various petroleum-based products, including crude oil, gasoline, and diesel fuel. PEEK’s hydrocarbon resistance is particularly valuable in offshore drilling operations, where gaskets must withstand harsh environments and constant exposure to hydrocarbons. The material’s ability to resist swelling and degradation in these conditions ensures reliable sealing and extends the lifespan of equipment.

14. Solvent resistance

The solvent resistance of PEEK gaskets is a crucial property that makes them suitable for use in diverse chemical environments. PEEK demonstrates excellent stability when exposed to a wide range of organic solvents, including ketones, esters, and alcohols. This resistance allows PEEK gaskets to maintain their sealing integrity in applications where other polymers might dissolve or degrade. PEEK’s solvent resistance is particularly valuable in industries such as pharmaceutical manufacturing and chemical processing, where exposure to various solvents is common.

15. Steam resistance

PEEK gaskets exhibit exceptional resistance to steam, making them ideal for high-temperature and high-pressure applications. This resistance allows PEEK to maintain its mechanical properties and dimensional stability even when exposed to superheated steam. PEEK’s steam resistance is particularly valuable in industries such as food processing, where steam sterilization is common, and in power generation, where steam turbines require reliable sealing solutions. The material’s ability to withstand prolonged exposure to steam ensures consistent performance and reduces maintenance requirements in these demanding environments.

16. Hot water resistance

The hot water resistance of PEEK gaskets is a critical feature that ensures their reliability in various applications. PEEK maintains its mechanical properties and dimensional stability even when continuously exposed to hot water, making it an excellent choice for sealing solutions in industries such as water treatment and food processing. PEEK’s hot water resistance allows it to outperform many other polymers in applications where prolonged exposure to high-temperature water is inevitable. This resistance translates to longer service life and reduced maintenance costs for equipment using PEEK gaskets.

17. Fuel resistance

PEEK gaskets demonstrate exceptional resistance to a wide range of fuels, including gasoline, diesel, and aviation fuels. This resistance is crucial in automotive, aerospace, and other transportation-related applications where exposure to various fuels is common. PEEK’s fuel resistance ensures that gaskets maintain their sealing properties and structural integrity even when in constant contact with fuel. This characteristic not only enhances safety but also extends the lifespan of fuel system components, reducing maintenance costs and improving overall system reliability.

18. Oil resistance

The oil resistance of PEEK gaskets is a standout feature that makes them indispensable in many industrial applications. PEEK maintains its properties when exposed to various types of oils, including mineral oils, synthetic oils, and engine oils. This resistance is particularly valuable in automotive and industrial machinery applications, where oil exposure is constant. PEEK’s oil resistance ensures that gaskets provide reliable sealing over extended periods, even in high-temperature and high-pressure environments. This characteristic contributes to improved equipment performance and reduced maintenance requirements.

19. Oxidation resistance

PEEK gaskets exhibit excellent resistance to oxidation, a property that significantly extends their service life in high-temperature and oxygen-rich environments. This resistance allows PEEK to maintain its mechanical and chemical properties even when exposed to oxidizing agents or elevated temperatures in the presence of oxygen. PEEK’s oxidation resistance is particularly valuable in aerospace and automotive applications, where components may be subjected to high temperatures and oxidizing conditions. The material’s ability to resist oxidation ensures that PEEK gaskets maintain their sealing effectiveness and structural integrity over extended periods, contributing to improved safety and reliability in critical systems.

20. Hydrolysis resistance

The hydrolysis resistance of PEEK gaskets is a crucial property that ensures their long-term performance in moist or aqueous environments. PEEK demonstrates exceptional stability when exposed to water or steam at elevated temperatures, resisting the breakdown of its polymer chains through hydrolysis. This resistance is particularly valuable in applications involving hot water, steam, or high-humidity environments. PEEK’s hydrolysis resistance allows it to maintain its mechanical properties and dimensional stability over extended periods, even in challenging conditions. This characteristic makes PEEK gaskets an excellent choice for industries such as food processing, medical sterilization, and geothermal energy, where exposure to hot, moist environments is common.

Chapter 3: Mechanical Properties

21. High tensile strength

PEEK gaskets exhibit exceptional tensile strength, making them ideal for applications requiring resistance to stretching and deformation under load. PEEK’s tensile strength typically ranges from 90 to 100 MPa, allowing it to withstand significant stress without failure. This property enables PEEK gaskets to maintain their integrity in high-pressure environments, such as hydraulic systems and aerospace applications.

22. Excellent wear resistance

The wear resistance of PEEK gaskets is outstanding, contributing to their longevity and reliability in demanding industrial settings. PEEK’s wear properties surpass those of many conventional materials, with a wear factor as low as 65 x 10^-6 mm^3/Nm. This exceptional wear resistance makes PEEK gaskets suitable for applications involving continuous friction or abrasive conditions, such as in pumps and compressors.

23. Superior abrasion resistance

PEEK gaskets demonstrate remarkable abrasion resistance, allowing them to maintain their sealing properties even in harsh, particle-laden environments. PEEK’s abrasion resistance is particularly valuable in industries such as mining and oil & gas, where exposure to abrasive materials is common. This property ensures that PEEK gaskets can provide reliable sealing performance over extended periods, reducing maintenance requirements and downtime.

24. High impact strength

The impact strength of PEEK gaskets is impressive, enabling them to withstand sudden loads and shocks without cracking or shattering. PEEK’s impact resistance is typically around 7.5 kJ/m^2 (notched Izod), making it suitable for applications subject to vibration or impact loading. This high impact strength contributes to the overall durability and reliability of PEEK gaskets in dynamic industrial environments.

25. Fatigue resistance

PEEK gaskets exhibit excellent fatigue resistance, allowing them to maintain their mechanical properties under cyclic loading conditions. PEEK’s fatigue performance is superior to many other thermoplastics, with a fatigue strength of approximately 59.3 MPa at 10^6 cycles. This property ensures that PEEK gaskets can withstand repeated stress cycles without premature failure, making them ideal for applications in rotating machinery and aerospace components.

26. Creep resistance

The creep resistance of PEEK gaskets is exceptional, enabling them to maintain their dimensions and sealing properties under sustained loads over time. PEEK’s creep behavior is characterized by low deformation rates, even at elevated temperatures. This property is crucial for applications requiring long-term dimensional stability, such as in high-pressure sealing systems and precision equipment.

27. Compressive strength

PEEK gaskets possess high compressive strength, allowing them to withstand significant compressive loads without deformation or failure. PEEK’s compressive strength typically ranges from 118 to 130 MPa, making it suitable for applications involving high contact pressures. This property ensures that PEEK gaskets can maintain effective sealing even under extreme compressive forces, such as those encountered in hydraulic systems and high-pressure vessels.

28. Dimensional stability

The dimensional stability of PEEK gaskets is outstanding, allowing them to maintain their shape and size across a wide range of environmental conditions. PEEK’s dimensional stability is characterized by low thermal expansion and minimal moisture absorption, ensuring consistent performance in varying temperature and humidity levels. This property is crucial for maintaining precise sealing tolerances in applications such as semiconductor manufacturing and aerospace components.

29. Low coefficient of friction

PEEK gaskets exhibit a low coefficient of friction, reducing wear and energy loss in dynamic sealing applications. PEEK’s friction properties are superior to many traditional sealing materials, with a coefficient of friction typically ranging from 0.25 to 0.35. This low friction characteristic makes PEEK gaskets ideal for applications involving sliding or rotating surfaces, such as in bearings and piston seals.

30. Flexibility

Despite its high strength and stiffness, PEEK gaskets offer a degree of flexibility that allows them to conform to irregular surfaces and accommodate minor misalignments. PEEK’s flexibility is balanced with its mechanical strength, providing effective sealing in applications where some compliance is required. This property makes PEEK gaskets versatile for use in various industrial applications, from automotive to chemical processing industries.

Chapter 4: Electrical Properties

31. Electrical insulation

PEEK gaskets excel in electrical insulation, making them ideal for applications requiring high dielectric strength. Their ability to resist electrical current flow prevents short circuits and ensures safety in electrical systems. For instance, PEEK gaskets in aerospace wiring provide reliable insulation even under extreme conditions.

32. Dielectric strength

The dielectric strength of PEEK gaskets is exceptional, typically ranging from 480 to 500 V/mil. This high dielectric strength allows PEEK to withstand strong electric fields without breaking down, making it suitable for high-voltage applications in power transmission.

33. Low dielectric constant

PEEK gaskets boast a low dielectric constant of approximately 3.2-3.3, which is advantageous in high-frequency applications. This property minimizes signal loss and interference, making PEEK ideal for use in telecommunications equipment.

34. Arc resistance

The arc resistance of PEEK gaskets is impressive, typically exceeding 300 seconds. This high resistance to electrical arcing makes PEEK an excellent choice for switchgear and circuit breaker applications where preventing arc-induced damage is crucial.

35. Volume resistivity

PEEK gaskets exhibit high volume resistivity, often exceeding 10^16 ohm-cm. This property ensures minimal current leakage through the material, making PEEK suitable for electrical insulation in harsh environments.

36. Surface resistivity

The surface resistivity of PEEK gaskets is typically around 10^16 ohms, which helps prevent the buildup of static charges. This characteristic is particularly valuable in electronics manufacturing where static discharge can damage sensitive components.

37. Dissipation factor

PEEK gaskets have a low dissipation factor, usually around 0.002-0.003 at 1 MHz. This property indicates minimal energy loss in alternating electric fields, making PEEK ideal for high-frequency applications in radar systems.

38. Comparative tracking index

The comparative tracking index (CTI) of PEEK is typically above 150 volts, indicating good resistance to electrical tracking. This property ensures that PEEK gaskets maintain their insulating properties even under conditions that might cause other materials to form conductive paths, making them suitable for use in outdoor electrical enclosures.

39. Electrostatic discharge properties

PEEK gaskets demonstrate excellent resistance to electrostatic discharge (ESD). This characteristic is crucial in electronics manufacturing and handling, where ESD can damage sensitive components. PEEK’s ability to dissipate static charges safely makes it an ideal material for ESD-sensitive environments.

40. Electromagnetic interference shielding

While pure PEEK is not conductive, it can be compounded with conductive fillers to provide electromagnetic interference (EMI) shielding. These PEEK composites offer a combination of excellent mechanical properties and EMI shielding, making them suitable for electronic enclosures in aerospace and defense applications.

Chapter 5: Performance in Extreme Environments

41. High-pressure applications

PEEK gaskets excel in high-pressure environments, making them ideal for demanding industrial applications. Their exceptional mechanical strength allows them to withstand pressures up to 30,000 psi without deformation or failure. This impressive capability stems from PEEK’s unique molecular structure, which provides superior resistance to compression set and creep. In oil and gas extraction, PEEK seals maintain integrity in deepwater drilling operations, where pressures can exceed 20,000 psi. The material’s low friction coefficient also reduces wear in dynamic sealing applications, extending the lifespan of critical components in high-pressure systems.

42. Vacuum environments

In vacuum applications, PEEK gaskets offer unparalleled performance due to their low outgassing properties. This characteristic is crucial in industries like semiconductor manufacturing and aerospace, where contamination from material off-gassing can compromise sensitive equipment or experiments. PEEK’s stability in vacuum conditions stems from its high glass transition temperature and excellent dimensional stability. The material retains its mechanical properties even in ultra-high vacuum environments, making it suitable for space-based applications where reliability is paramount. Additionally, PEEK’s resistance to atomic oxygen erosion further enhances its suitability for use in low Earth orbit environments.

43. Radiation resistance

PEEK demonstrates remarkable resistance to various forms of radiation, including gamma rays, X-rays, and UV radiation. This property makes PEEK gaskets invaluable in nuclear power plants, medical imaging equipment, and spacecraft. The material’s radiation resistance is attributed to its aromatic backbone structure, which absorbs and dissipates radiation energy effectively. In nuclear applications, PEEK seals maintain their integrity even after exposure to high radiation doses, ensuring the safety and reliability of critical systems. PEEK’s ability to withstand sterilization processes involving radiation also makes it an excellent choice for medical devices and pharmaceutical manufacturing equipment.

44. Corrosive environments

PEEK’s exceptional chemical resistance makes it an ideal material for gaskets in corrosive environments. The polymer remains stable when exposed to a wide range of acids, bases, and organic solvents, outperforming many metals and other plastics. In chemical processing plants, PEEK gaskets provide reliable sealing for pipes and vessels containing aggressive chemicals. The material’s resistance to hydrolysis also makes it suitable for applications involving hot water and steam. PEEK’s stability in corrosive media extends to harsh offshore environments, where it resists degradation from saltwater and hydrogen sulfide, common challenges in oil and gas production.

45. Aerospace applications

In the aerospace industry, PEEK gaskets find extensive use due to their combination of light weight, high strength, and resistance to extreme conditions. The material’s ability to perform reliably at both high and low temperatures makes it ideal for aircraft engines, where temperatures can range from -65°C to over 260°C. PEEK’s low smoke and toxicity characteristics in case of fire also contribute to its popularity in aerospace applications. PEEK components in aircraft hydraulic systems provide excellent sealing performance while reducing overall weight, contributing to fuel efficiency. The material’s resistance to jet fuels and hydraulic fluids further enhances its suitability for aerospace use.

46. Oil and gas applications

PEEK gaskets have become indispensable in the oil and gas industry, where they face some of the most challenging operating conditions. In downhole applications, PEEK seals withstand high temperatures, pressures, and exposure to aggressive chemicals. The material’s resistance to rapid gas decompression makes it particularly valuable in high-pressure gas environments. PEEK’s performance in sour gas applications, where hydrogen sulfide is present, surpasses that of many traditional sealing materials. In offshore platforms, PEEK gaskets provide reliable sealing in valves, pumps, and compressors, contributing to the overall safety and efficiency of operations.

47. Cryogenic applications

At extremely low temperatures, PEEK retains its mechanical properties, making it an excellent choice for cryogenic applications. The material’s low thermal contraction and high dimensional stability prevent leakage in sealing applications at temperatures as low as -200°C. In liquefied natural gas (LNG) processing and transportation, PEEK gaskets maintain their sealing effectiveness, preventing costly and dangerous leaks. PEEK’s performance in cryogenic valves ensures reliable operation in the handling of super-cooled gases and liquids. The material’s low friction coefficient at cryogenic temperatures also contributes to the smooth operation of moving parts in cold environments.

48. Marine environments

In marine applications, PEEK gaskets offer superior resistance to saltwater, marine growth, and UV radiation. The material’s hydrolysis resistance prevents degradation in prolonged exposure to seawater, making it ideal for underwater equipment and offshore structures. PEEK’s low moisture absorption ensures dimensional stability in marine environments, maintaining effective sealing even under changing humidity conditions. PEEK seals in marine propulsion systems provide reliable performance in harsh conditions, resisting wear from abrasive particles in seawater. The material’s resistance to marine biofouling also reduces maintenance requirements for underwater equipment.

49. Clean room compatibility

PEEK’s low particle shedding and outgassing properties make it highly suitable for clean room environments in semiconductor manufacturing, pharmaceutical production, and medical device assembly. The material’s resistance to most cleaning agents and sterilization methods ensures it maintains its integrity in stringent cleanliness protocols. PEEK gaskets in clean room equipment provide reliable sealing without contaminating sensitive processes. The material’s ability to withstand repeated sterilization cycles, including autoclaving and gamma radiation, makes it ideal for reusable components in clean room applications.

50. UV resistance

While PEEK is inherently resistant to UV radiation, its performance can be further enhanced through additives and surface treatments. This UV resistance makes PEEK gaskets suitable for outdoor applications and equipment exposed to sunlight or artificial UV sources. In solar panel manufacturing, PEEK components maintain their properties despite prolonged UV exposure. UV-stabilized PEEK formulations offer even greater resistance to photo-oxidation, extending the lifespan of gaskets in outdoor industrial equipment. The material’s color stability under UV exposure also contributes to its use in applications where appearance is important alongside functional performance.

Chapter 6: Durability and Longevity

51. Extended service life

PEEK gaskets offer exceptional durability, translating to an extended service life that far surpasses conventional sealing materials. Their remarkable resistance to thermal degradation allows them to maintain structural integrity even under prolonged exposure to high temperatures. This longevity is particularly valuable in industries where frequent maintenance shutdowns can be costly. For instance, in oil and gas applications, PEEK gaskets can withstand the harsh conditions of deep-sea drilling operations for extended periods, reducing the need for frequent replacements and minimizing downtime.

52. Resistance to aging

One of the standout features of PEEK gaskets is their impressive resistance to aging. Unlike rubber or plastic alternatives that may degrade over time, PEEK maintains its mechanical and chemical properties even after years of service. This resistance to environmental stress cracking ensures that PEEK gaskets remain effective long after other materials would have failed. In automotive applications, for example, PEEK gaskets in engine components can withstand the constant exposure to heat, vibration, and chemicals without showing signs of aging or degradation.

53. Weathering resistance

PEEK gaskets exhibit excellent weathering resistance, making them ideal for outdoor and exposed applications. Their ability to withstand UV radiation, moisture, and temperature fluctuations without significant degradation sets them apart from many other sealing materials. This resistance to environmental factors is particularly beneficial in aerospace and renewable energy sectors, where components are often exposed to harsh weather conditions. Solar panel installations, for instance, rely on PEEK gaskets to maintain seal integrity despite constant exposure to the elements.

54. Minimal degradation

The minimal degradation of PEEK gaskets under various operating conditions is a key factor in their growing popularity across industries. Unlike many polymers that may break down or lose their properties over time, PEEK maintains its structural and functional integrity even in challenging environments. This resistance to chemical and mechanical wear ensures that PEEK gaskets continue to perform effectively, maintaining tight seals and preventing leaks long after installation. In chemical processing plants, where exposure to corrosive substances is common, PEEK gaskets demonstrate remarkable resilience against degradation.

55. Reduced maintenance frequency

The exceptional durability of PEEK gaskets directly translates to reduced maintenance frequency, offering significant cost savings and operational benefits. By outlasting conventional gasket materials, PEEK minimizes the need for frequent replacements, reducing downtime and maintenance costs. This is particularly valuable in critical industrial applications where unscheduled shutdowns can be extremely costly. For example, in power generation facilities, PEEK gaskets in turbine components can operate for extended periods without requiring replacement, ensuring continuous operation and improved efficiency.

56. Equipment downtime reduction

PEEK gaskets play a crucial role in reducing equipment downtime across various industries. Their ability to withstand extreme conditions without failure means that machinery and systems can operate for longer periods without interruption. This improved reliability is especially important in continuous process industries, where even short periods of downtime can result in significant production losses. In the semiconductor manufacturing industry, for instance, PEEK gaskets in high-purity fluid handling systems help maintain clean room conditions and reduce the frequency of system shutdowns for maintenance.

57. Stress crack resistance

The exceptional stress crack resistance of PEEK gaskets is a key factor in their durability and longevity. Unlike many polymers that may develop cracks under sustained stress, PEEK maintains its structural integrity even in high-stress applications. This resistance to crack propagation is crucial in applications where gaskets are subjected to constant pressure or cyclic loading. In hydraulic systems, for example, PEEK gaskets can withstand the repeated stress cycles without developing cracks, ensuring long-term reliability and safety.

58. Load deformation resistance

PEEK gaskets exhibit outstanding resistance to load deformation, maintaining their shape and sealing properties even under high pressures. This ability to resist compression set and maintain dimensional stability is crucial for long-term sealing performance. In applications where gaskets are subjected to variable loads, such as in automotive transmission systems, PEEK’s resistance to deformation ensures consistent sealing over time, reducing the risk of leaks and improving overall system reliability.

59. Long-term flexibility

The long-term flexibility of PEEK gaskets is a significant advantage in applications requiring sustained elasticity. Unlike some materials that may become brittle or lose their flexibility over time, PEEK maintains its elastic properties even after prolonged use. This sustained flexibility is crucial in dynamic sealing applications where gaskets must repeatedly deform and recover to maintain an effective seal. In aerospace applications, for instance, PEEK gaskets in aircraft engine components maintain their flexibility despite exposure to extreme temperatures and pressures, ensuring consistent performance throughout the aircraft’s service life.

60. Embrittlement resistance

PEEK gaskets demonstrate superior resistance to embrittlement, a common failure mode in many polymeric materials. This resistance to becoming brittle, even under harsh conditions or prolonged exposure to chemicals, ensures that PEEK gaskets maintain their sealing effectiveness over extended periods. In cryogenic applications, where many materials become brittle and fail, PEEK gaskets retain their ductility and sealing properties. This embrittlement resistance is particularly valuable in the liquefied natural gas (LNG) industry, where gaskets must maintain their integrity at extremely low temperatures.

Chapter 7: Versatility and Compatibility

61. Static sealing applications

PEEK gaskets excel in static sealing applications due to their exceptional chemical resistance and thermal stability. These gaskets maintain their integrity under extreme pressures and temperatures, making them ideal for use in flanged connections in chemical processing plants. Their low creep characteristics ensure long-term sealing performance, even in environments with thermal cycling. PEEK gaskets are particularly effective in applications where traditional elastomeric materials may degrade, such as in the presence of aggressive chemicals or high-temperature steam.

62. Dynamic sealing applications

In dynamic sealing scenarios, PEEK gaskets showcase their versatility. Their low coefficient of friction and high wear resistance make them suitable for rotary and reciprocating applications. These properties are crucial in equipment like pumps and compressors, where continuous motion between sealing surfaces occurs. PEEK’s ability to maintain its mechanical properties at elevated temperatures allows for its use in high-speed rotating equipment, where frictional heat generation is a concern.

63. Compatibility with various sealing designs

PEEK’s adaptability extends to various sealing designs, including O-rings, lip seals, and custom profiles. Its excellent machinability allows for the creation of intricate sealing geometries, optimizing performance for specific applications. PEEK can be molded or machined into spiral wound gaskets, metal-jacketed gaskets, or kammprofile designs, offering flexibility in sealing solutions across industries.

64. Food and beverage industry compliance

In the food and beverage sector, PEEK gaskets meet stringent regulatory requirements. They comply with FDA 21 CFR 177.2415 for food contact applications, ensuring safety in processing equipment. PEEK’s resistance to high-temperature cleaning and sterilization processes, such as CIP (Clean-In-Place) and SIP (Sterilize-In-Place), makes it an ideal choice for maintaining hygiene standards in food production lines.

65. Medical and pharmaceutical applications

PEEK gaskets find extensive use in medical and pharmaceutical equipment due to their biocompatibility and sterilization resistance. They are employed in drug delivery systems, diagnostic equipment, and surgical instruments. PEEK’s ability to withstand repeated sterilization cycles, including autoclave and gamma irradiation, ensures long-term reliability in critical medical applications.

66. Semiconductor industry suitability

The semiconductor industry relies on PEEK gaskets for their purity and outgassing properties. These gaskets are crucial in maintaining clean room environments and preventing contamination in sensitive manufacturing processes. PEEK’s low particle generation and resistance to plasma etching make it suitable for wafer processing equipment and other high-purity applications in the semiconductor sector.

67. Automotive applications

In the automotive industry, PEEK gaskets are utilized in various systems, including fuel injection, transmission, and exhaust components. Their resistance to automotive fluids and high-temperature stability make them ideal for sealing critical engine components. PEEK gaskets contribute to improved fuel efficiency and reduced emissions by maintaining tight seals under extreme operating conditions.

68. Aerospace industry compatibility

The aerospace sector leverages PEEK gaskets for their lightweight properties and resistance to hydraulic fluids. These gaskets are used in aircraft fuel systems, hydraulic actuators, and engine seals. PEEK’s ability to perform under wide temperature ranges and its fire-retardant properties make it an essential material in aerospace sealing applications, contributing to aircraft safety and performance.

69. Chemical processing industry use

In chemical processing, PEEK gaskets provide exceptional resistance to a wide range of corrosive chemicals. They are employed in reactors, distillation columns, and heat exchangers, where exposure to aggressive media is common. PEEK’s stability in acidic and alkaline environments ensures long-term sealing integrity, reducing maintenance requirements and improving process efficiency in chemical plants.

70. Energy sector applications

The energy sector benefits from PEEK gaskets in various applications, including oil and gas extraction, power generation, and renewable energy systems. These gaskets withstand the high pressures and temperatures encountered in deep-sea drilling operations and geothermal power plants. In wind turbines, PEEK gaskets provide reliable sealing for gearboxes and hydraulic systems, contributing to the longevity and efficiency of renewable energy equipment.

Chapter 8: Environmental Benefits

71. Recyclability

PEEK gaskets offer excellent recyclability, contributing to sustainable manufacturing practices. Unlike traditional gasket materials, PEEK can be mechanically recycled multiple times without significant loss of its mechanical properties. This characteristic allows for the creation of a circular economy within industries, reducing waste and conserving resources. The recycling process typically involves shredding used PEEK gaskets, followed by remelting and remolding into new products.

72. Energy efficiency contribution

PEEK gaskets play a crucial role in enhancing energy efficiency across various applications. Their low friction coefficient reduces energy losses in moving parts, leading to improved overall system efficiency. In automotive applications, PEEK gaskets contribute to fuel efficiency by maintaining tight seals under extreme conditions, reducing leakage and optimizing engine performance. The material’s lightweight nature also contributes to reduced energy consumption in transportation and machinery.

73. Waste reduction

The use of PEEK gaskets significantly contributes to waste reduction in industrial processes. Their exceptional durability and resistance to wear mean they need to be replaced less frequently than traditional gasket materials. This longevity translates to less waste generated over time. Additionally, PEEK’s chemical resistance prevents degradation in harsh environments, further extending their service life and reducing the need for frequent replacements.

74. Low emissions

PEEK gaskets contribute to low emissions in several ways. Firstly, their excellent sealing properties prevent leaks of potentially harmful substances, reducing fugitive emissions in industrial settings. In automotive applications, PEEK gaskets help maintain optimal engine performance, leading to more efficient combustion and reduced exhaust emissions. Furthermore, the production process of PEEK itself generates fewer emissions compared to some traditional materials, contributing to a lower overall carbon footprint.

75. Environmental regulation compliance

PEEK gaskets are well-suited to meet stringent environmental regulations across various industries. They comply with numerous international standards for environmental safety and performance, including ISO 23936 and NORSOK M-710 for oil and gas applications. PEEK’s low outgassing properties make it suitable for clean room environments and aerospace applications where material stability is crucial. Its resistance to hydrolysis and steam sterilization also makes it compliant with strict medical industry regulations.

76. Lubricant reduction

The use of PEEK gaskets can lead to significant reductions in lubricant requirements. PEEK’s inherently low coefficient of friction allows for smooth operation in many applications without the need for extensive lubrication. This property is particularly beneficial in industries where lubricant contamination is a concern, such as food processing or pharmaceutical manufacturing. The self-lubricating properties of PEEK can extend the life of mating components and reduce maintenance needs, further contributing to environmental benefits through reduced resource consumption.

77. System efficiency improvement

PEEK gaskets contribute to overall system efficiency improvements in various ways. Their excellent thermal stability allows for consistent performance across a wide temperature range, ensuring optimal sealing even in fluctuating conditions. The material’s dimensional stability under stress helps maintain tight tolerances, crucial for efficient operation of precision machinery. In hydraulic and pneumatic systems, PEEK gaskets’ resistance to extrusion helps maintain system pressure, leading to improved energy efficiency and reduced power consumption.

78. Carbon footprint reduction

The use of PEEK gaskets contributes to carbon footprint reduction throughout their lifecycle. During production, PEEK manufacturing processes are generally less energy-intensive compared to some traditional gasket materials. In application, PEEK’s lightweight nature and durability contribute to fuel efficiency in transportation and reduced maintenance needs, indirectly lowering carbon emissions. The material’s recyclability further reduces its carbon footprint by minimizing the need for virgin material production. PEEK’s role in enhancing system efficiency across various industries also leads to reduced energy consumption and associated carbon emissions.

79. Leakage prevention

PEEK gaskets excel in leakage prevention, a critical factor in environmental protection. Their exceptional chemical resistance and stability prevent degradation and maintain seal integrity even in harsh chemical environments. The material’s ability to withstand high pressures and temperatures makes it ideal for critical sealing applications in industries like oil and gas, where leaks can have severe environmental consequences. PEEK’s dimensional stability ensures consistent sealing performance over time, reducing the risk of leaks due to material creep or relaxation.

80. Sustainable manufacturing support

PEEK gaskets support sustainable manufacturing practices in several ways. The material’s long service life reduces the frequency of replacements, minimizing production demands and associated environmental impacts. PEEK’s recyclability supports closed-loop manufacturing processes, reducing waste and conserving resources. The material’s high performance in extreme conditions allows for the design of more efficient and durable machinery, supporting overall sustainability in industrial operations. PEEK’s compatibility with advanced manufacturing techniques like 3D printing also enables more efficient, on-demand production, reducing waste and inventory requirements.

Chapter 9: Cost-Effectiveness

81. Overall system cost reduction

PEEK gaskets offer significant overall system cost reductions through their exceptional durability and performance. While the initial investment may be higher, PEEK’s long-term value becomes evident in reduced maintenance needs and extended equipment lifespans. By withstanding extreme temperatures and harsh chemicals, PEEK gaskets minimize the frequency of replacements, leading to lower labor costs and decreased production downtime. Their ability to maintain sealing integrity under high pressures also prevents costly leaks and associated safety hazards.

82. Downtime cost minimization

One of the most significant advantages of PEEK gaskets is their ability to minimize costly downtime. PEEK’s superior wear resistance and thermal stability allow equipment to operate continuously for extended periods without the need for frequent maintenance shutdowns. This increased uptime translates directly to improved productivity and profitability across industries like oil and gas, chemical processing, and aerospace.

83. Maintenance cost reduction

PEEK gaskets substantially reduce maintenance costs through their exceptional longevity and resistance to degradation. Unlike traditional gasket materials, PEEK maintains its properties even when exposed to aggressive chemicals, extreme temperatures, and high pressures. This resilience means fewer replacements are needed over time, cutting down on both material costs and labor expenses associated with maintenance activities. Additionally, PEEK’s low coefficient of friction minimizes wear on mating surfaces, further extending the lifespan of entire systems.

84. Energy cost savings

The use of PEEK gaskets can lead to notable energy cost savings in various applications. Their excellent insulating properties help maintain thermal efficiency in high-temperature systems, reducing heat loss and associated energy consumption. In fluid handling systems, PEEK gaskets’ ability to maintain tight seals under pressure minimizes leakage and pumping losses, contributing to improved overall energy efficiency. PEEK’s lightweight nature also plays a role in energy savings, particularly in transportation applications where reduced weight translates to improved fuel economy.

85. Weight reduction potential

PEEK gaskets offer significant weight reduction potential compared to traditional metal gaskets, making them particularly valuable in aerospace and automotive applications. Their high strength-to-weight ratio allows for the design of lighter components without compromising on performance or durability. This weight reduction can lead to improved fuel efficiency in vehicles and aircraft, as well as easier handling and installation of equipment in various industrial settings.

86. Metal alloy replacement

PEEK gaskets serve as excellent replacements for metal alloys in many applications, offering comparable or superior performance with added benefits. Their resistance to corrosion and chemical attack often surpasses that of many metals, making them ideal for use in harsh environments. PEEK’s ability to withstand high temperatures while maintaining its mechanical properties allows it to replace metals in applications where thermal stability is crucial. This substitution can lead to cost savings not only in material expenses but also in processing and manufacturing costs.

87. Part consolidation opportunities

The versatility of PEEK allows for innovative part consolidation opportunities, potentially reducing the number of components in a system. This consolidation can lead to simplified assembly processes, reduced inventory requirements, and lower overall manufacturing costs. For example, complex gasket designs incorporating multiple sealing surfaces or integrated features can be molded as a single PEEK component, eliminating the need for separate parts and assembly steps.

88. Equipment reliability improvement

PEEK gaskets significantly enhance equipment reliability across various industries. Their consistent performance under extreme conditions ensures that sealed systems maintain their integrity over extended periods. This reliability translates to fewer unexpected failures, reduced maintenance interventions, and improved overall equipment efficiency. In critical applications such as aerospace or oil and gas operations, PEEK’s reliability can be crucial in preventing costly and potentially dangerous system failures.

89. Inventory cost reduction

Adopting PEEK gaskets can lead to substantial inventory cost reductions. Their extended lifespan and resistance to degradation mean fewer replacement parts need to be kept in stock. Additionally, PEEK’s versatility allows for the use of standardized gasket designs across multiple applications, further streamlining inventory management. This consolidation of inventory not only reduces storage costs but also simplifies procurement processes and minimizes the risk of obsolescence for stockpiled parts.

90. Customization cost-effectiveness

While PEEK gaskets may have a higher initial cost compared to some traditional materials, their customization cost-effectiveness becomes apparent in specialized applications. PEEK’s excellent machinability and molding capabilities allow for the creation of complex, application-specific gasket designs without the need for expensive tooling or lengthy production processes. This flexibility enables manufacturers to optimize gasket performance for unique requirements, potentially eliminating the need for multiple components or over-engineered solutions, ultimately leading to long-term cost savings.

Chapter 10: Processing and Manufacturing Advantages

91. Injection molding capability

PEEK’s exceptional thermal properties make it ideal for injection molding, allowing for the creation of complex gasket geometries with tight tolerances. The high melt flow index of PEEK enables it to fill intricate mold cavities, resulting in gaskets with precise dimensions and smooth surfaces. This capability is particularly valuable in applications requiring custom-shaped seals, such as those found in aerospace components or medical devices.

92. Precision machining

The unique molecular structure of PEEK lends itself well to precision machining techniques. CNC machining of PEEK gaskets allows for incredibly tight tolerances and smooth surface finishes, crucial for applications where sealing performance is paramount. This precision ensures optimal fit and function, even in the most demanding industrial environments.

93. 3D printing compatibility

Advancements in additive manufacturing have made 3D printing of PEEK gaskets a reality, opening up new possibilities for rapid prototyping and small-batch production. This technology enables the creation of complex geometries that would be difficult or impossible to achieve through traditional manufacturing methods, providing engineers with greater design flexibility and reduced lead times.

94. Filler incorporation

PEEK’s versatility extends to its ability to incorporate various fillers, enhancing its properties for specific applications. Carbon fiber-reinforced PEEK, for example, offers increased strength and stiffness, making it suitable for high-load bearing gaskets in automotive and aerospace industries. Glass fiber and graphite fillers can also be added to improve wear resistance and reduce friction in dynamic sealing applications.

95. Welding and bonding properties

PEEK’s thermoplastic nature allows for various joining techniques, including welding and bonding. Ultrasonic welding of PEEK gaskets provides strong, hermetic seals without the need for adhesives, making it ideal for applications in the medical and food processing industries where cleanliness is critical. Additionally, PEEK’s chemical resistance allows for bonding with specialized adhesives, expanding its application range in multi-material assemblies.

96. Compression molding suitability

For larger or thicker gaskets, compression molding offers an excellent processing option for PEEK. This method allows for the production of high-quality, dense parts with minimal internal stresses. Compression molded PEEK gaskets exhibit superior mechanical properties and dimensional stability, making them suitable for heavy-duty industrial applications where reliability under extreme conditions is essential.

97. Color customization

PEEK can be easily colored during the manufacturing process, allowing for gasket identification and aesthetic customization. This feature is particularly useful in complex systems where quick visual identification of different seals is necessary. Colored PEEK gaskets can aid in assembly processes, reduce errors, and enhance overall system organization.

98. Composite structure potential

The ability to create composite structures with PEEK as the matrix material opens up a world of possibilities for gasket design. PEEK composites can be tailored to meet specific performance requirements by incorporating fibers, nanoparticles, or other reinforcing materials. This allows for the development of gaskets with optimized properties for particular applications, such as improved chemical resistance or enhanced thermal conductivity.

99. Marking and labeling ease

PEEK’s surface properties make it amenable to various marking and labeling techniques, including laser marking and pad printing. This capability ensures that PEEK gaskets can be easily identified and traced throughout their lifecycle, a critical feature for quality control and regulatory compliance in industries such as aerospace and medical devices.

100. Intricate profile design capability

The processing advantages of PEEK allow for the creation of gaskets with highly intricate profiles. Complex cross-sections, undercuts, and multi-lip designs can be achieved through advanced molding and machining techniques. This capability enables the development of high-performance sealing solutions that can address challenging sealing requirements in applications ranging from high-pressure hydraulic systems to sensitive electronic enclosures.

Conclusion

And there you have it – a whirlwind tour of 100 compelling advantages that position PEEK gaskets as the ultimate choice for demanding industrial applications. From their exceptional thermal and chemical resistance to their unmatched versatility and cost-effectiveness, PEEK gaskets are the high-performance solution you’ve been searching for across a myriad of industries.

As the CEO of FLUIDMEC, I am thrilled to share this comprehensive list with you, hoping it aids in making informed decisions about your sealing solutions. But hey, I’m all ears! Did I miss any advantages you’ve experienced with PEEK gaskets? Drop a comment below, and I’ll ensure this list is updated with your valuable insights. Together, let’s continue to push the boundaries of sealing technology and drive innovation in our industries.

If you’re in the market for top-quality hydraulic seals, oil seals, or gaskets, look no further than FLUIDMEC. Our commitment to excellence ensures that you’ll receive products with high cost performance and long working life. Reach out to us at kevin@aqua-mantis-985900.hostingersite.com and let’s discuss how we can meet your sealing needs!